Nicknamed ‘The Black Pearl’, Jeff Buckham’s CR500 hybrid could just be the finest supermoto special we’ve ever seen…

Building a special is a tricky business. Forget the engineering side of things for a minute, because that very much depends on how ambitious/bonkers you are. No, what I’m talking about applies to every single bike build: getting the look and feel of it right. It’s sometimes possible to spend peanuts and with a few carefully chosen parts and modifications end up with something outstanding. Likewise, wave your credit card around and, sure, you can buy lots of trick shiny parts that make everyone coo. But, when all’s said ‘n’ done and you’re trying to hide the card statement from the wife, you’re not necessarily guaranteed a good looking, or even good-performing, bike. I believe the phrase is ‘the whole is greater than the sum of its parts.’

Earlier this year an email pinged into my inbox, the message was nothing but a camera-phone photo of a half-built bike on a hydraulic workstand. It was wearing carbon wheels and fancy suspension but that wasn’t what drew me in. No, it was the fact that the instantly recognisable key components – engine, frame, swingarm, – were not from the same machine, or even the same marque. The motor was from a CR500, the chassis that of a CRF450R, the swingarm from a V-twin Aprilia. I recognised the sender and immediately made a call. ‘We NEED to feature that bike!’ His grainy photo had had the desired effect…

Phil John was the man at the other end of the phone, the ever-smiling face of 1st Class Customs in the Welsh valleys town of Caerphilly. Alongside building chops, bobbers, trikes and just about anything the warped minds and crazed imaginations of the local riders can come up with, Phil also knows his way around a dirtbike. He’s prepped Dakar bikes for Craig Bounds and Tamsin Jones, and rides a WR-F himself.

At the time the bike was not a million miles away from being finished, so along with his list of jobs which were left to complete he was also under strict instruction to let me know as soon as it saw the light of day. The call came in late April…

Diamond Mine

‘With Phil’s custom background and my cosmetic background we just bounced ideas of each other’, explained the bike’s owner, Jeff Buckham. Owning a mobile car bodywork repair company (Smart Motive in south Wales) Jeff’s bike was always likely to be well finished and highly detailed, even more so when you know that this isn’t the first ultra-trick supermoto he’s built.

Jeff blames ‘being from the Welsh valleys’ for his love of bikes, at nine or ten everyone in the area had a dirtbike and they filled his spare time until the age of 17, when he passed his test and took to the road. Compensation from a bad accident allowed Jeff to trade up from a 250LC to an RD500 YPVS, and so followed a long line of sportsbikes.

A ban saw Jeff head back to the dirt, and with the rising popularity of supermotos at the time, once he had his licence back he stuck a pair of wheels in the CRF450 he had at the time and road registered it. And so the SM obsession began.

What followed was a long line in ‘home-converted’ motards – CRF450Rs and Xs, a Husky 610 and a KX250. In 2008 Jeff bought a CRF450R to use off-road but found it ‘a bit much’ so instead reverted to his default setting of slipping a pair of 17in wheels into it. However, this was going to be no ordinary supermoto – he wanted to make it the best SM possible…

Although Jeff freely admits to liking his ‘bling’, the build wasn’t ostentatious or garish. Known as ‘The Black Pearl’, only the Ohlins suspension front and rear shone bright amongst the muted greys and rich blacks of carbon and titanium. No lairy bolt kits or flaming-dragon-wrapped-in-barbed-wire-and-surrounded-by-skulls graphics here, thankyouverymuch.

By his own admission Jeff ‘went nuts’ on the build, and bought all of the parts new. Looking at the considerable spec, it’s easy to see where almost 13 grand went.

With its tuned engine and high-spec chassis, it’s hard to believe that Jeff got bored of the CRF but that’s exactly what happened. So the ‘Pearl found a new home in Scotland and thoughts turned to a new project, dubbed ‘The Black Diamond’…

Diamond Cut

Having seen a few CR500 hybrids (2T motor in an alloy frame) on the ‘net, Jeff decided to build one using a late model CRF chassis. Unlike those which use the earlier two-stroke CR frame, Jeff knew that there was a hell of a lot of work involved in getting the old stroker lump into the four-stroke’s frame, so he asked Phil if he was up for it…

Often, when building a hybrid, it’s hard to purchase just an engine and just a frame, instead you need to look at buying complete bikes. And that was just the case here. Jeff saw a 1991 CR500 advertised locally and snapped it up, before posting a ‘wanted’ ad on the web for a CRF chassis. This led to a 2007 CRF450 which had grenaded its motor. Twice. The owner had just spent £1400 having the engine rebuilt when it blew-up for a second time, and he simply couldn’t face that kind of expenditure again. Jeff ’ripped the bloke’s arm off’ when he offered him the bike for just £650 quid.

With the engine out of the CR, and just the rolling chassis of the CRF, Jeff took the parts down to Phil’s workshop and work commenced. Although it fired-up okay, the motor was fully rebuilt ‘you don’t do a project like this without stripping the engine’, noted Phil – and a good job too, as removing the head revealed a huge crack in the piston!

New bearings and seals were used throughout, the crank balanced, and once Stan Stephens had refreshed the bore and played with the porting a new, slightly oversize, Prox piston was slipped in. ‘It’s not in a mental state of tune because I wanted it to be reliable. Stan gave it what he called an “enduro” tune.’

As the bike was intended for road use, Jeff wanted to be confident that it wouldn’t boil-up in traffic so ordered a Coolhead – a machined aluminium cylinder head featuring improved cooling and interchangeable combustion chambers that allow you to alter the compression ratio. However this, along with the Boyesen clutch- and ignition-covers were left on the shelf and the original parts put in place so that the motor could be taken in and out whilst the frame was being modified without scratching the new components.

Phil worked a great deal of magic on the CRF frame in order to get the motor into place. Firstly, the 500’s expansion chamber necessitated the Y-piece on the frame’s downtube be moved 3.5in higher. In order to achieve this some people would simply cut it out and add some box section in the gap underneath, but not Phil. Instead he chopped it out, raised it and then created a pair of new lower frame rails. Leaving one original rail in place while he worked on the other side allowed him to obtain the exact same curvature, before replicating it on the other side. The result is a frame that at first glance appears factory standard… except with better welding!

Positioning the engine brought about a further problem. The CR500 motor is a sizeable lump, and on such conversions there’s often precious little clearance between the spark plug and the bottom of the fuel tank. One way to get around this is to gently heat the plastic tank and press it up out of the way. That wasn’t an option here, as Jeff would be using a carbon fibre tank, so Phil had to ensure that the engine sat low in the frame. A set of engine mounts were fabbed from billet and there’s now plenty of clearance for the sparkplug without resorting to a shorty plug.

Diamond Pattern

Having seen a KX-F running the old style of Aprilia RXV ‘trellis’ swingarm, Jeff liked the idea of using the same rear-end on the hybrid. Why use a swingarm from the RXV dirtbike, rather than the SXV supermoto? Well the SXV’s swinger is actually much wider than that of the enduro bike, in order to squeeze in its far wider rear rim.

Jeff obtained the necessary swingarm measurements and passed them on to Phil, who confirmed that it would work with the Honda frame and engine. In fact, whilst describing the modifications needed Phil gave a wry smile and said ‘to be honest, it was a piece of p1$$!’ The ‘top-hat’ bearings in the centre of the swingarm had to be ground down around 1mm and then it all but slipped into place. To top it off, using the RXV part doesn’t even alter the wheelbase!

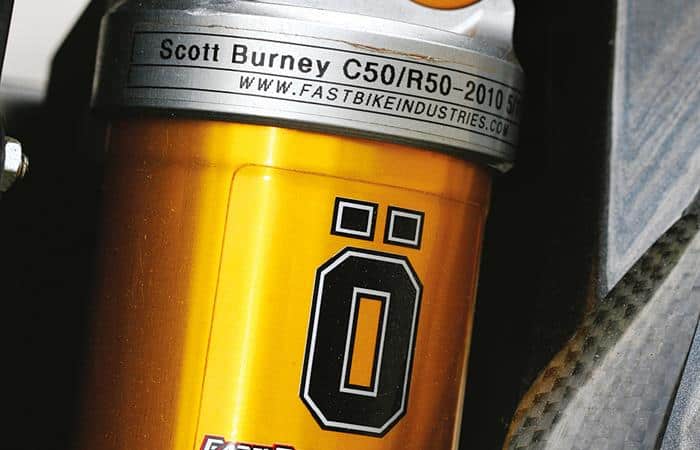

Things weren’t quite so simple when mounting the Ohlins TTX shock. Jeff bought the shock from AMA supermoto racer Scott Burney after Stateside friend and fellow bling-fiend, Shawn West, contacted him to say that Scott had the trick Swedish suspension unit for sale. Due to the huge chamber on the Ohlins, Phil couldn’t get it to locate correctly on the top shock mount, and was forced to machine a new bolt in order to get everything in place. He then mated it to the linkage with a set of freshly-made spacers and the Aprilia bolts.

In the Black

Whereas the parts for the Black Pearl were bought new, Jeff decided to save some money on the Diamond and source himself some bargains, shopping around to get the best deals and using certain secondhand parts. The new 50mm Marzocchi front forks were picked-up online, complete with triple clamps, though they were originally intended to be bolted to the front of a KTM enduro bike. Jeff had the company fit them with a Honda stem, and when they arrived he shipped them straight off to Pro Action to have them shortened by 40mm and revalved to suit SM use.

Knowing that he wanted a steering damper, Jeff tried to find an Ohlins unit to match the TTX shock, though everywhere he went (even the USA) he got the same answer: ‘it’s on back order’. Eventually he turned one up in Ireland, and the seller only wanted £400 for it. As it was designed to fit a CRF, the triple clamps came in for a spot of machining in order to get it to fit.

The BST carbon wheels came from within the UK supermoto race paddock, and had seen some use so required a little cosmetic fettling. With Jeff’s expertise in bodywork finishing this wasn’t a big issue, more of a problem was the fact they were designed to fit an SMR KTM. Still, at the start of the project Phil had reassured Jeff ‘we can do anything, we can make anything fit!’ and sure enough he did… using a set of Triumph Speed Triple wheel bearings.

Another problem then reared its head: that of the rear disc. Finding one that matched the KTM hub and lined up with the Aprilia caliper proved nigh-on impossible and it looked like one was going to have to be specially made. In a last ditch effort to find one Phil asked Craig Bounds if he’d bring down all of the discs he had spare in his workshop and see if anything would fit. And as luck would have it, one of them did; that of a KTM 690 Rally. It’s not the prettiest of discs – Jeff would prefer something a little more skeletal, or perhaps a wavey part, rather than the chunky desert race disc – but it’s doing its job and has saved both the time and expense of a one-off item.

Right from the start, Jeff wanted a twin silencer exhaust system on the hybrid, something rarely seen on two-stroke machines but a feature that, if executed well, would look oh-so good. Just to be sure that he wasn’t going to ruin the bike’s power output, he gave respected south Wales engine tuner Royston Edwards a call. Royston confirmed that as it’s the expansion chamber that’s the crucial part of a 2T exhaust, running twin silencers wouldn’t stifle the engine, so Jeff cracked-on with sourcing the necessary parts.

A search on eBay threw up a New Old Stock titanium Akrapovic system for a CR250R, running carbon endcaps on its silencers. At the bargain price of £480 it was far too good to pass-up.

Jeff took the Slovenian pipework, along with a Pro Circuit ‘Platinum’ expansion chamber, down to Phil’s workshop and while Phil modified the subframe in order to get the silencers attached Jeff worked on modifying the left-hand sidepanel to allow for the extra pipe. This he did by heating the plastic, bending it to the desired shape, and then rapidly cooling it. Having sliced 60mm from the end of the front pipe, Phil machined a collar to mate it to the Akrapovics and the two ends slipped neatly into place.

Black Light

When it came to the bodywork Jeff knew exactly what he wanted – carbon fibre… every last panel. Czech company Pro Carbon supplied the tank, rad panels and front fender, the latter requiring some surgery in order to shrink it down to size. ‘It was nicely styled’ Phil remembered, ‘but just way too big.’ Unfortunately the rear fender was unavailable, so Jeff made do with a plastic version covered in carbon wrap. A far higher quality than the old ‘grey and black squares printed on sticky-backed plastic’ fake carbon, this stuff is heavily textured and from a distance looks like un-lacquered carbon. The airbox also remains plastic, though it is a brand new OE part, matched to a CR250 boot in order to fit the new Keihin PWK33 carb.

You’ve probably noticed from the pictures that the carb has been polished, along with parts such as the suspension linkage, rear caliper, kickstart, and (reshaped) rear brake lever. With the Coolhead coming factory-polished, it was decided that various other parts might look good in a mirror-finish, so they were sent down to ‘Skymmy’ at Caerphilly Metal Polishers who got them glinting.

The frame, subframe and swingarm were also sent away for a new finish, though the company who performed the work didn’t get it quite how Jeff wanted. The graphite grey powdercoat was supposed to have a satin finish, something Jeff had used on his 450, and instead ended up gloss. Although he wasn’t particularly chuffed by this, it wasn’t the end of the world and a set of carbon frameguards prevent his boots from dulling the frame spares.

With the frame finished the engine could be brought up to snuff and slipped into place. The Boyesen covers were bolted on, the clutch side hiding a Talon basket and EBC Dirt racer clutch-pack, and a Boyesen rad valve was added too. All of the fasteners were replaced with new stainless items. The barrel and engine cases were also vapour-blasted and then treated to black ‘Harley Davidson’ crackle-finish paint – a bold move but one that has certainly paid off. It looks fantastic!

The motor was plumbed into a pair of Motocross Parts UK rads, which by now you won’t be surprised to hear came in for some modifications. Phil first tried CR500 rads, though these were too tall, too skinny and looked awful. So aftermarket it was then, and the frame modifications meant fabricating new lower mounts and chopping a large wedge out of the lower portion of each rad in order to get them onboard. The inlet and outlet pipes were then adapted to suit the CR hoses.

Jeff came across a set of silicon hoses that would do the job, unfortunately they were red. Still, the price was too good to ignore, so they made it onto the 500 as a stop-gap until black versions, which are on back order, arrive. Mind you, you’ll need a keen eye to spot ‘em, as they’ve been temporarily wrapped in black tape so as not to spoil the look!

Diamonds Are Forever

While much of this was going on, a Beringer brake system was on order with the French company. Having gone down the polished route with the cylinder head, rear caliper etc, Jeff thought the front stopper might look good in the same finish. Whilst Beringer offer this amongst the usual plethora of colours, it’s rare for them to do polished supermoto brakes – it’s mainly ordered for choppers and cruisers – so it would take longer than normal as they didn’t have the parts on the shelves. Still, Jeff was prepared to wait, so he placed the order. And waited. And waited… And eventually, once the estimated delivery date was but a distant memory, the parts finally leap-frogged the Channel and landed on his doorstep.

The Gallic-made kit has a great reputation in SM circles, so the fully-floating 310mm cast iron disc, radial four-piston caliper, radial master cylinder were worth the wait, even if it was just a little bit frustrating! To complement the master cylinder, Jeff ordered a matching clutch lever to add a sense of symmetry to the carbon-coated bars. Protecting the new levers are a set of Cycra handguards, adorned with Infinity carbon flags (another part which came via Jeff’s Stateside connection, Shawn).

The finishing touch, and a crucial one at that, is the custom graphics kit. Jeff didn’t want to hide the carbon panels behind vast sheets of vinyl, though nor did he want the bike to look dull and dowdy in plain black. So he enlisted the help of Grant at GFX Designs, who produced a set of subtle grey and black decals. In order to ensure that they fitted they were printed on a regular CRF template, from which Jeff trimmed away the excess material to leave just the logos. It’s the perfect balance between showing off the glistening weave and covering up the panels.

Diamond Back

One question we always ask any specials builder is ‘is there anything that you’d change?’ We know Jeff’s not a huge fan of the rear disc, and would prefer it if ALL of the bodywork were carbon, so leaving those things aside, what would you alter Jeff? ‘Well, I’m not happy with the ignition. They’re the original 22-year-old parts so I’m going to change the coil and stator.’ Visually, the CR is all but finished, though when the motor is run up to temperature it’s clear that something in the ignition system is breaking down – above the evil cackle from the expansion chamber you can hear the engine missing and Jeff reported that it eventually cut-out on the dyno. By the time you read this it’ll be in rude health, sparking strong with all new parts.

Both Jeff and Phil have poured a huge amount of effort into the CR and it certainly shows – the bike is absolutely outstanding. There’s something very special, very evocative, about those big ol’ big two-stroke motors of old, and slotting them into a taut and lightweight modern chassis is, for many, the ultimate single-cylinder motorcycle. To go one further and fit perhaps the sexiest swingarm of all time, plus twin pipes, just takes things up a notch.

Jeff wanted the bike to not only look good but also handle superbly, and by retaining the standard geometry and adding high-end and carefully set-up suspension I don’t doubt that it’ll go round bends rather well too. But it is the ‘look’ that really blows you away. The CR looks right from every angle, the stance is spot-on, and whilst it does feature some highly desirable top-spec components, there isn’t an ostentatious, overtly bling feel to it. Instead it simply looks, well, classy. The Black Diamond really is greater than the sum of its parts!

Huge thanks to: Ross John and the good folk at Machen Quarry for helping out with the photo location.

Jeff would like to thank:

• Phil at 1st Class Customs

• Shawn West

• Supermoto Daz / www.smdoffroad.co.uk

• Grant at GFX Designs

• The guys on www.supermotoforum.co.uk